PRODUCT INTRODUCTION (WORKING PRINCIPLE, COMPONENT PARTS, OPERATINGMODE

Working Principle

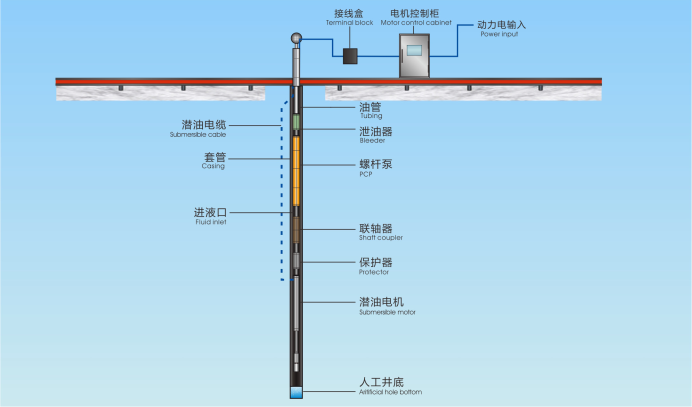

After the pump unit of the ESPCP system is lowered down into the well, the power is transmitted through the power cable to the submersible motor under the well to drive the progressive cavity pump(PCP) and the fliud in the well is then raised up onto the ground with the pressure boost of PCP.

Electric Submersible Progressing Cavity Pumping(ESPCP) System Flow Chart

Product Components

| ESPCP System | ||

| Module | Surface Equipment | Down-hole Equipment |

| Main Module | Wellhead | PCP |

| Motor Control Cabinet/Servo System | Shaft coupler | |

| Juncyion box | Protector and Submersible Cable | |

| Transformer | Submersible Motor | |

Operation Mode

During operation, the electricity is transmitted via the submersible cable from the servo control system on the ground to the purpose-designed permanet magnetic synchronous motor in the down-hole for stepless speed regulation so that the motor can run at a low soeed but a high torgue output, driving PCP to extract oil through the protector and thr shaft coupler.

THE KEY COMPONENT OF SYSTEM

Submersible Permanent Magnetic Synchronous Motor

Low speed, large torque output

No slip loss

No rator loss

Efficiency up to 80%

Multi-stage arrangement

Motor Control Cabinet

Free of encoder vector control

Motor ON/OFF self-protection

System operating status monitoring

Oil extraction under constant dynamtic fluid lever

Digital remote intelligent control

Progressing Cavity Pump(PCP)

High pump efficieny, long life

Continous and smooth suction, no pressure incentive effect

Good adaptability to sand and wax can work with high effvienvy in high viscosity crude oil